Good for severe environments with oil, due to their long useful service life with oil gasoline, hydraulic fluids, and hydro carbon solvents. Outstanding resistance to a wide range of solvents, including petroleum based. Very low compression set, even at high temperatures. Not recommended for use with ketones.

$286.86

| Weight | 1.57 lbs |

|---|---|

| Dimensions | 7 × 4.375 × 4.375 in |

| Size | |

| Valve Type | |

| Body Cap Material | |

| End Cap Thread 1 | |

| End Cap Thread 2 | |

| Sleeve Material |

Long Description edits only available in Pinch Valve Elementor Template.

| Weight | 1.57 lbs |

|---|---|

| Dimensions | 7 × 4.375 × 4.375 in |

| Size | |

| Valve Type | |

| Body Cap Material | |

| End Cap Thread 1 | |

| End Cap Thread 2 | |

| Sleeve Material |

Install directly in the fluid line or put a tee in the line and attach the valve to the leg of the tee.

Hold rods and shafts in a fixed position. Use for linear or rotational motion control.

Control fluidized dry material.

Use actuation pressure to close the valve at “normal” operation pressures for the system.

Modulate surges in pressure or flow rate in a piping system.

Control fluidized dry material.

Can eliminate the need for periodic shutdown of the system to empty a receiver.

Airpinch pinch valves can be a real problem solver for demanding control applications. Threaded NPT or BSPT pinch valves housings are available in molded polypropylene and nylon, or anodized aluminum. Choose from a variety of elastomers for optimum compatibility and performance with your controlled media.

Airpinch pinch valve housings are precision molded of engineering grade plastics. This results in a rugged valve at an economical price. Molded pinch valves are lightweight and well suited for use where corrodible and heavy metal valves won’t work.

Airpinch pinch valves give you fast, positive shut-off of most industrial materials, liquids, and dry flowables. They will close tightly on suspended particulate materials in liquids. Even highly viscous materials are no problem.

Airpinch pinch valves are versatile because of their unique flow-through design. They provide rapid operation; full, unobstructed flow; and complete closure. Mount them in any position—even fully submerged.

Richway’s Airpinch™ valves use compressed air, or fluid, to compress the rubber sleeve inside of the valve body to shut off media flow. Operating pressures for controlled material vary depending on sleeve elastomer and valve size. They can range from a moderate vacuum (up to 26″ Hg) to a maximum of 90 psi when controlling with air.

Required actuation pressure is generally 20 to 40 psi greater than media pressure. It’s recommended that the actuation air pressure be set just high enough to get complete valve closure. Using higher actuation pressure than is required to get complete media shut off can reduce sleeve life. Use of actuation pressure above 90 psi is not recommended.

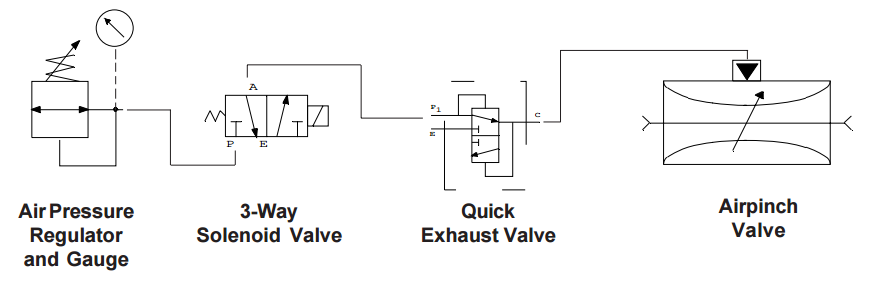

As shown above this is the recommended configuration for controlling an air pinch valve. The regulator is used to set the actuation air pressure and a three-way solenoid controls the regulated air signal going to the valve. Once the pressure to the air pinch valve is released, it’s exhausted back through the three-way valve, allowing the sleeve to open. A quick exhaust valve isn’t required for operation, however in applications where the solenoid is a long distance from the air pinch valve, it’ll allow quick operation by allowing the actuation pressure to exhaust more quickly.

By design AirpinchTM brand pinch valves are normally open and require constant pressure for complete closure. Therefore, a loss of control pressure will allow the valve to open. In the event of sleeve failure, controlled material can enter the actuation system.

CAUTION: Airpinch pinch valves should not be used in applications where such conditions could cause system damage or failure. The designer must recognize sleeve failure can occur at any time.

The actuation valve controlling the Airpinch must have free exhaust to allow the Airpinch to open. A solenoid, manual, or air-pilot operated 3-way control valve is required. A check valve cannot be used between the Airpinch and exhaust port of the controlling valve. Using a QEV can improve valve opening response time.

If you have any questions or need help about a product, feel free to contact us Mon – Fri 8-5pm CST.

If you have any questions or need help about a product, feel free to contact us Mon – Fri 8-5pm CST.

Website Designed by Running Robots

"*" indicates required fields