The way work gets done

Airpinch™ Industrial Valves

We provide affordable air pinch valves that are rugged and long lasting. The rubber sleeves are easily replaceable to decrease downtime and save you money. Our valves are versatile because of their unique flow-through design. They provide rapid operation, full unobstructed flow, and complete closure. Mount them in any position — even fully submerged.

Showing 1–16 of 169 resultsSorted by price: high to low

— Get the perfect fit

Airpinch™ Pinch Valves Dimensions

| Valve | Housing Length | Valve O.D. | End Cap Threads | Control Inlet |

|---|---|---|---|---|

| 1/4" | 3.5" | 1.25" | 1/4" | 1/8" |

| 3/8" | 2.875" | 1.75" | 1/4", 3/8" | 1/8" |

| 5/8", 3/4" | 4" | 2.25" | 3/4", 1" | 1/4" |

| 1" | 5.5" | 3.5" | 1" | 1/4" |

| 1 1/4" | 5.5" | 3.5" | 1 1/4" | 1/4" |

| 1 1/2" | 7" | 4" | 1 1/2" | 3/8" |

| 2" | 10" | 6.25" | 2" | 3/8" |

— Selecting Rubber Sleeves

Airpinch™ Pinch Valves Material Specifications

This information is intended to introduce the multitude of considerations that exist when determining sleeve selection and anticipated performance. In all cases, the end user is responsible for determining the suitability of a sleeve material for a specific application. Actual operating conditions and materials can greatly affect sleeve performance.

A sampling of factors to consider when selecting rubber sleeves follows:

- Will the sleeve be exposed to fluids, oil, water, solvents, or chemical solutions?

- Will the sleeve be exposed to gases, liquid vapors, ozone, or high or low temperatures?

- Will the sleeve be involved in food or drug processing?

- When working with oils, inks, and solvents, determine in detail the brand, type, and grade of fluid.

- Give consideration to the fact that lubricating oils may be present in compressed air systems.

***Richway Industries, Ltd., can assume no responsibility for the accuracy and/or completeness of this information when determining sleeve selection or compatibility for any particular application. ***

| Common Name | Available Types | Chemical Definition | Compression Set | Abrasion Resistance | Tear Resistance | Solvent Resistance | Oil Resistance | Temperature Usage |

|---|---|---|---|---|---|---|---|---|

| Buna N, Nitrile, NBR | B60 | Butadiene Acrylonitrile | Good | Excellent | Good | Good to Excellent | Good to Excellent | 0 F to 190 F |

| EPDM | E30 E60 | Ethylene Propylene Diene Monomer | Fair | Good | Fair | Poor | Poor | -30 F to 275 F |

| Natural Rubber, NR | R60 R60W | Polyisoprene | Excellent | Excellent | Excellent | Poor | Poor | -40 F to 150 F |

| Neoprene®, CR | N60 | Polychoroprene | Good | Excellent | Good | Fair | Fair | -10 F to 225 F |

| Silicone, VMQ ** | I20 I35 NSFI50 I60 | Polysiloxane | Good to Excellent | Fair to Poor | Poor | Poor | Fair to Poor | -70 F to 425 F |

| Viton®, FKM, Fluorel® | V65 | Fluorinated Hydrocarbon | Good | Good | Good | Excellent | Excellent | 0 F to 450 F |

** Product(s) not available for purchase online. Please contact us for product and ordering information.

— Where to use

Airpinch™ Pinch Valves Applications

Gauge protection

Install directly in the fluid line or put a tee in the line and attach the valve to the leg of the tee.

Motion control

Hold rods and shafts in a fixed position. Use for linear or rotational motion control.

Pneumatic conveying

Control fluidized dry material.

Pressure relief

Use actuation pressure to close the valve at “normal” operation pressures for the system.

Surge protection

Modulate surges in pressure or flow rate in a piping system.

Throttling

Control fluidized dry material.

Vacuum receiver

Can eliminate the need for periodic shutdown of the system to empty a receiver.

— Why Richway Is the Way

Benefits of Airpinch™ Pinch Valves

Compatible

Airpinch™ pinch valves can be a real problem solver for demanding control applications. Threaded NPT or BSPT pinch valves housings are available in molded polypropylene and nylon, or anodized aluminum. Choose from a variety of elastomers for optimum compatibility and performance with your controlled media.

Economical

Airpinch™ pinch valve housings are precision molded of engineering grade plastics. This results in a rugged valve at an economical price. Molded pinch valves are lightweight and well suited for use where corrodible and heavy metal valves won’t work.

Positive

Airpinch™ pinch valves give you fast, positive shut-off of most industrial materials, liquids, and dry flowables. They will close tightly on suspended particulate materials in liquids. Even highly viscous materials are no problem.

Versatile

Airpinch™ pinch valves are versatile because of their unique flow-through design. They provide rapid operation; full, unobstructed flow; and complete closure. Mount them in any position—even fully submerged.

How Pinch Valves Work

— Built to last

Operating Pressures

Richway’s Airpinch™ valves use compressed air, or fluid, to compress the rubber sleeve inside of the valve body to shut off media flow. Operating pressures for controlled material vary depending on sleeve elastomer and valve size. They can range from a moderate vacuum (up to 26″ Hg) to a maximum of 90 psi when controlling with air.

Required actuation pressure is generally 20 to 40 psi greater than media pressure. It’s recommended that the actuation air pressure be set just high enough to get complete valve closure. Using higher actuation pressure than is required to get complete media shut off can reduce sleeve life. Use of actuation pressure above 90 psi is not recommended.

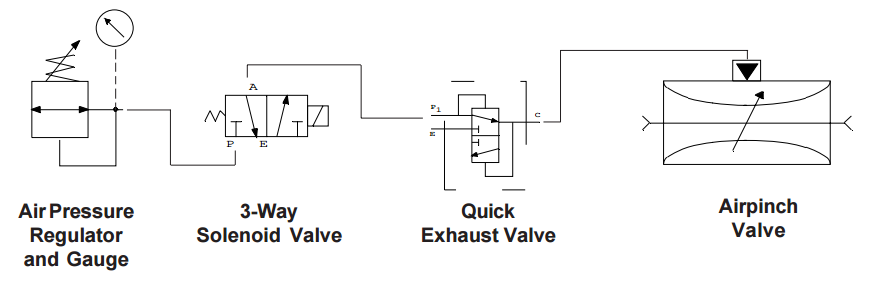

Recommended Configurations

As shown above this is the recommended configuration for controlling an air pinch valve. The regulator is used to set the actuation air pressure and a three-way solenoid controls the regulated air signal going to the valve. Once the pressure to the air pinch valve is released, it’s exhausted back through the three-way valve, allowing the sleeve to open. A quick exhaust valve isn’t required for operation, however in applications where the solenoid is a long distance from the air pinch valve, it’ll allow quick operation by allowing the actuation pressure to exhaust more quickly.

By design Airpinch™ brand pinch valves are normally open and require constant pressure for complete closure. Therefore, a loss of control pressure will allow the valve to open. In the event of sleeve failure, controlled material can enter the actuation system.

CAUTION: Airpinch pinch valves should not be used in applications where such conditions could cause system damage or failure. The designer must recognize sleeve failure can occur at any time.

The actuation valve controlling the Airpinch must have free exhaust to allow the Airpinch to open. A solenoid, manual, or air-pilot operated 3-way control valve is required. A check valve cannot be used between the Airpinch™ and exhaust port of the controlling valve. Using a QEV can improve valve opening response time.