Cellular concrete can be produced many different ways. For any given application the project size, project type, and required material properties will drive the best production method and subsequent equipment requirements. Regardless of the project and material requirements, the use of the right equipment and input materials, along with proper quality control measures, will ensure success with your project.

The first method for producing cellular concrete is also the simplest method, which is the batch production method. As implied, cellular concrete is produced in batches. The base slurry is prepared in a mixer and then externally generated foam is added. Mixer types can vary greatly, including colloidal mixers and ready mix transit mixers. Even batch mixing in a bucket with a handheld drill mixer can produce good results.

To achieve the desired density, mix design calculations must be done to determine how much foam to add to a given volume of base slurry. The required foam volume, along with the foam generator output, is then used to calculate the amount of time that foam must be injected into the mixer. Our mix design calculator is an excellent tool for calculating foam dose proportions and time.

Foam is typically added to the mixer while it is mixing and should always be the last thing added. It is important to have the other materials thoroughly mixed before any foam is added to the mixer.

Once the required amount of foam is added, the mixer continues mixing until the foam is completely mixed in homogeneously. (When using a colloidal mixer, the foam cannot be mixed in with the high shear mixing pump, but rather should be added on the secondary tank.)

After the cellular slurry is mixed homogeneously, placement of the material should begin. A commonly asked question is “How long can you leave a cellular slurry mixing?” The answer is there are too many factors to provide a universally applicable answer. Foam quality, cellular density, mixer type, base slurry mix design, and ambient temperature all factor in.

Assuming that any of the mentioned factors aren’t too far out of line, in many cases a mix could be left in a mixer for a minimum of 30 minutes, and in many cases much longer, before needing to be placed. If a cellular mix is going to be left in a mixer for an extended period of time, it’s best to allow the material to continue mixing, although at a slow rate.

Generally speaking the batch mix process is better suited for smaller production requirements and also requires a smaller investment in equipment to get into cellular concrete. The batch process can be easier to control density without a lot of experience. Also, density control can be easier to manage if the volumes of material required are smaller or a lot of starts and stops are needed during placement.

The second method for producing cellular concrete is known as the continuous production process. In many applications cellular concrete, or foamed cement, must be pumped to the point of placement. If a pump is being used, then foam can be injected and mixed in-line on the pump hose, rather than needing to be mixed in a mixer.

This production method can provide many advantages, including higher production rates, higher production volumes for any given mixer size, and the ability to adjust the cellular density “on the go.”

A comparison of the two production methods with a project requiring 100 yards³ (76.46 m³) of 30 PCF material looks like this: Using the batch production method, 10 ready mix trucks would be required to deliver and mix the required amount of material. Each truck would deliver approximately three yards³ (2.29 m³) of base slurry, to which seven yards³ (5.35 m³) of foam would be added. Additionally, a separate pump would be required on-site assuming the material would need to be pumped to the point of placement.

Using the continuous method, only four trucks would be required, each delivering approximately seven and half yards³ (5.73 m³) of base slurry. The full truckloads of slurry are discharged from the mixer into the hopper of the cellular concrete pump, and the 70 yards³ (53.52 m³) of foam required to attain 100 yards³ (76.46 m³) of 30 PCF material is then injected and mixed in-line while the material is being pumped.

The continuous production process is a “dynamic” production process, meaning that all of the inputs—i.e., slurry pumping rate, foam production rate, system and line pressures can change—and as they do the volume and density of the material being produced will change.

Because of these factors this process typically requires more knowledge and experience, and most importantly equipment that is designed for this type of production. However, with proper training and equipment, an operator can quickly learn and take advantage of the continuous production method.

With either given production method there are a number of quality control factors that will affect the success in production. Below are some of the universally applicable guidelines that should be followed.

The base slurry must be mixed well. Thorough mixing needs to be done to ensure all of the dry materials are well dispersed within the slurry before being mixed with foam.

For batch production, the base slurry should have all of the cementitious materials and water mixed together before foam is added to the mixer. If any dry materials were added after foam it’s highly likely that once the dry material comes in contact with the foam, it would cause the foam bubbles to break.

For any cellular concrete production when preparing slurry in a drum style mixer, care should be taken to ensure that powder does not “cake” on the sides of the drum, or “head pack” at the bottom of the drum.

A good indicator that a slurry hasn’t been mixed well enough is portland balls, or agglomeration of the portland, within the slurry. Often times this can be observed when the slurry is being discharged from the mixer.

Depending on the size of the agglomerations, they may be visible or they may only be discovered by feeling the slurry with your hands. When agglomerations do occur, it indicates the cementitious materials aren’t dispersed well and can lead to lower compressive strengths of the cellular concrete. The use of water reducers, plasticizers, or dispersion ad-mixes can help with this issue.

Although when using any ad-mixtures, testing for compatibility must be done to ensure the ad-mix doesn’t have an adverse reaction with the foam. A worst-case scenario would be that the ad-mix would cause the foam bubbles to break, causing the cellular slurry to collapse either in the mixer or once placed.

Portland does have a shelf life. If Portland is allowed to sit unused for too long, the hydration process can begin, resulting in poor cellular concrete. This is most notable with bagged materials that can be purchased at retail outlets—although it does occur when Portland is stored anywhere for too long.

The discovery of hard balls of Portland powder within a bag, or storage container, is a key indicator that Portland is too old to reliably be used for production. If used, the cellular material may have lower than expected strength, or may also result in a slurry that won’t set before exhibiting some collapse of the cellular material.

A good foam generator will likely be able to make what appears to be a good foam for use in cellular concrete—with most any foam concentrate—even dish soap.

However, if the foam concentrate hasn’t been designed to withstand the rigors of the mixing process and the placement process (especially pumping), the cellular material will in many cases collapse or crush the foam bubbles during the production and placement process. Lighter densities and higher lifts exacerbate the problem.

A key indicator of good cellular concrete foam concentrate is the ability to withstand higher material lifts. ASTM C869 is the standard set for foam concentrates used in the production of cellular concrete. The standard is designed to test the durability of the foam and its ability to remain intact throughout the mixing and pumping process.

At minimum it’s recommended that an ASTM-certified foam be used for producing cellular concrete, although it doesn’t mean all foams that meet the standard are equal.

As mentioned before, lift height is a good measure of a foam’s quality, and all ASTM-certified foams are not equal in their performance of this measure. All things being equal, the higher lift that can be achieved, the better the foam concentrate.

Generally speaking, the smaller the foam bubble, the better durability the cellular slurry will have during production and placement.

Good foam generation equipment will produce a foam that exhibits “shaving cream” consistency and very small bubble size. Beyond that, a good foam generator will allow the operator to control foam output, foam density, and water to concentrate ratio, and be consistent every time it’s used.

When considering foam generation equipment, as with any equipment purchase, consider the overall build quality and construction. Equipment that’s designed for long-term durability and serviceability is crucial to ensure year after year consistent performance and foam quality.

Although there is no industry standard, most foam manufacturers recommend a 40:1 ratio of water to concentrate. This may vary depending on foam. However, Richway recommends this as a starting point with our CMX concentrate.

Also, we recommend a starting point for foam density of three pounds per cubic foot. Again, this may vary depending on manufacturer. Typically a 40:1 ratio and 2-3 PCF foam density will allow the production of most any cellular concrete mix design. However, depending on the application, the water to concentrate ratio and foam density can be varied quite a bit.

If you think of a foam bubble as simply air which is contained within a film of surfactant and water, then the surfactant is the adhesive that gives the bubble its strength and allows the bubble to survive during the mixing and placement process. If a higher water to concentrate ratio is used, the thinner the bubble wall will be. This is also true of a lighter-density foam.

That being said, there are many instances in which a higher water to concentrate ratio and lower foam density can be used successfully, even in lighter density material (i.e., 30 PCF), and more demanding placements (i.e., longer pumping distances and lift heights). With careful process control and testing, users will likely find this to be true.

As with any cementitious material, producing sample cylinders for testing is an important component of quality control. ASTM 495 is a standard that gives the proper procedure for producing test cylinders of cellular concrete.

There are a few salient points to be made here though. When producing cylinders of cellular concrete, don’t rod the material. Fill the cylinder halfway full and tap the sides to remove any trapped pockets of air. When full, once again tap the sides and strike the top off before capping.

Once cylinders have been made, allow them to sit for at least 24 hours before handling or transportation. They should be put in a vibration free location, and ideally somewhere the temperature can be somewhat controlled, like a cooler. If they are handled/vibrated too much during the initial set, the bubbles can pop and cause a collapse of material, or micro stresses can occur, causing lower than expected strength results.

Cylinders should be allowed to air dry sufficiently before they are compression tested. Testing a cylinder that still contains moisture will give a low strength break.

As well, drying cylinders in an oven should only be done for checking the dry weight and not for compression testing. We typically figure the weight difference between wet and dry material to be about a 5% decrease in density. However, this should be checked for any given mix design as variances in material inputs will give variances between wet and dry weights.

Before cylinders are broke, it’s important to prepare them by using a capping compound. This helps ensure end-to-end squareness and takes care of any edge defects that occurred during the demolding process.

Using a properly sized compression testing machine is important for accurate results. A press that is rated for a maximum capacity of 10 times the expected material strengths is a good guideline.

In the case of testing 3 X 6 cylinders of 30 PCF material, we’d expect on average 100 psi compressive strength, or approximately 7000 lbs total compressive force. So ideally a cylinder break press with a maximum capacity of about 10,000 lbs. would be used. Smaller presses can be used also, as long as they’re not underrated.

Because the strength of cellular concrete is directly correlated to the density, it’s extremely important to check the density of the material throughout any given project.

In many cases projects specs may only call for one cylinder (that will be compression tested) every hour or per certain number of trucks, or yards produced. However, sampling material density more often, especially at the start of a project, helps ensure all of the equipment and material is dialed in properly for the project.

Not monitoring density often enough or at the right location can cost a lot of money. If the material density is too light, it may not meet the compressive strength requirements. If the material is too heavy, it means more material inputs were used than needed, costing more money than needed.

When producing and placing material with the batch method, typically material can be sampled as it’s going from the mixer directly into the point of placement. Sampling should be done by discharging material from the mixer into a large vessel, such as a five-gallon bucket, and then scooping material from there into test cylinders.

However, if using a pump for placement, taking samples can be more challenging. Samples should be taken at the point of placement, or as close to the point of placement as possible. If the cellular concrete is mixed in a mixer and density is checked as it goes into the pump, there may likely be a difference in density at the end of the pump hose.

When cellular concrete is pumped (meaning that foam has been added before going into the pump), some of the bubbles can get crushed, or pop, during the process. However this isn’t always the case as there are multiple factors at play. If it does occur it will result in higher density material at the point of placement.

When taking a sample from the end of a pump hose, don’t simply put the cylinder into the stream of material to fill the cylinder. Capture the full cross section of the material stream into a larger container, such as a five-gallon bucket, and scoop material into the cylinder.

The reason for this is if there’s variance in cross section of the material stream, the portion from which it was sampled may not give a good representation of the material density in aggregate.

Many times cellular concrete is being pumped into a blind bulkhead as found in slip lining applications, or into underground abandonments such as sewer lines or underground tanks. In these types of scenarios it can be impossible to access material coming directly from the end of the hose.

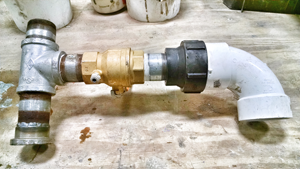

A common method for obtaining sample material is to create a “test tee” at the bulkhead, or where the pump hose attaches to the point of access. A tee with a ball valve on it will allow sample material to be taken for checking density. Ideally the ball valve is the same size as the pumping hose so that again, the full stream of material can be discharged into sampling container.

As shown in the picture, the test tee has three-inch elbow, which would be turned downward, so the material can be more easily contained. The three-inch elbow is used on a two-inch line to help slow the velocity of the material exiting the tee. If a test tee isn’t needed, stepping the hose size up the last few feet is a good way to slow material velocity down when production rates are high, making material sampling more manageable.

When pumping cellular concrete there can be many challenges to ensure the proper density is attained at the end of the pump hose where the material is being placed. Pump type, hose size, and hose length relative to the density; mix design; and production rate are all important factors.

The production method used and equipment are other critical aspects that should be considered when placing cellular concrete with a pump. You can read more about cellular concrete pumping and placement here.

If you have any questions or need help about a product, feel free to contact us Mon – Fri 8-5pm CST.

If you have any questions or need help about a product, feel free to contact us Mon – Fri 8-5pm CST.

Website Designed by Running Robots

"*" indicates required fields